Introduction

An

automatic edging machine is a multi-functional fully automatic lens edger which

is able to process both glass and plastic lenses. It is designed for highly

efficient edging operation, easy to operate and gives precision control on lens

size and shape.

automatic edging machine is a multi-functional fully automatic lens edger which

is able to process both glass and plastic lenses. It is designed for highly

efficient edging operation, easy to operate and gives precision control on lens

size and shape.

An

automatic lens edger helps to increase edging productivity, as well as

flexibility through fast, accurate edging of simple and complex edge types. It

help in the efficient and fast production of straight bevels, inclined bevels, rimless

with drills, grooves, and polishing in addition to T-bevels and steps backs.

With the automatic edging machine, even the most complicated jobs are easily

edged.

automatic lens edger helps to increase edging productivity, as well as

flexibility through fast, accurate edging of simple and complex edge types. It

help in the efficient and fast production of straight bevels, inclined bevels, rimless

with drills, grooves, and polishing in addition to T-bevels and steps backs.

With the automatic edging machine, even the most complicated jobs are easily

edged.

History of automatic edging machine

The automatic edging machine was invented in

September 1953 and in July 25th 1967 and was granted patent right in

the United State in July 25th 1967 with Patent No 3,332172. In 2006,

the automatic edging machine enabled the most delicate jobs to be carried out

comfortably with customized setting.

September 1953 and in July 25th 1967 and was granted patent right in

the United State in July 25th 1967 with Patent No 3,332172. In 2006,

the automatic edging machine enabled the most delicate jobs to be carried out

comfortably with customized setting.

Diagram

direction:

(1) outer cover (voice-proof)

(2) water-proof inner cover

(3) head pressure adjusting knob

(4) the head

(5) the sensor of head base(cursor)

(6) lens chuck

(7) power switch

(8) wheels

(9) horizontal adjustment foot

(10) operation panel

direction:

(1) outer cover (voice-proof)

(2) water-proof inner cover

(3) head pressure adjusting knob

(4) the head

(5) the sensor of head base(cursor)

(6) lens chuck

(7) power switch

(8) wheels

(9) horizontal adjustment foot

(10) operation panel

Operation procedure of automatic edging machine

A. Preparations

a. Turn

power switch on and open water supply cock.

power switch on and open water supply cock.

b. Press

(TEST)switch and check that water is supplied

(TEST)switch and check that water is supplied

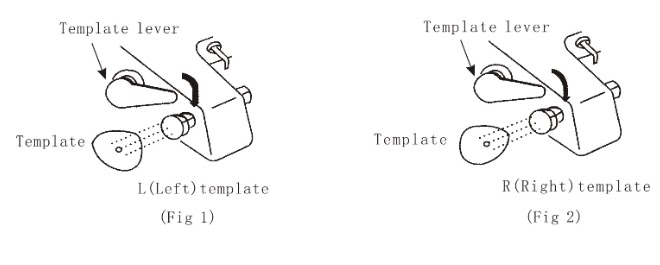

B.

Fitting

template

Fitting

template

·

Put left and right template as illustrated in Fig.

1 and Fig. 2 above.

Put left and right template as illustrated in Fig.

1 and Fig. 2 above.

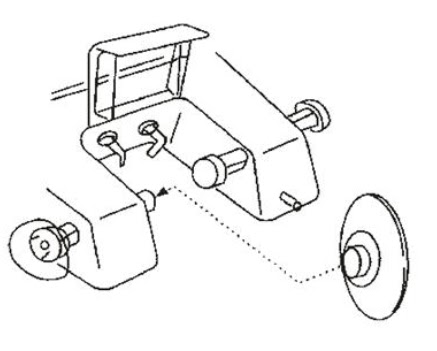

A. Fix the lens

Match the upper point of sucker with the one of the shaft as in Fig. 3

above.

above.

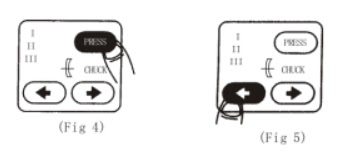

A. Clamping

lens

lens

Select lens clamping with PRESS button as shown in Fig. 4

·

Select

clamp pressure

Select

clamp pressure

a.

(low):

For high refractive glass lens

(low):

For high refractive glass lens

b.

(medium):

For glass lens and Columbia Resin (CR)

lens

(medium):

For glass lens and Columbia Resin (CR)

lens

c.

(high):

For CR lens

(high):

For CR lens

·

Clamp the lens with chunk button

Clamp the lens with chunk button

·

When

pressed lightly one time, it automatically clamp lens

When

pressed lightly one time, it automatically clamp lens

·

When

relax button lightly, clamp will loosen lens

When

relax button lightly, clamp will loosen lens

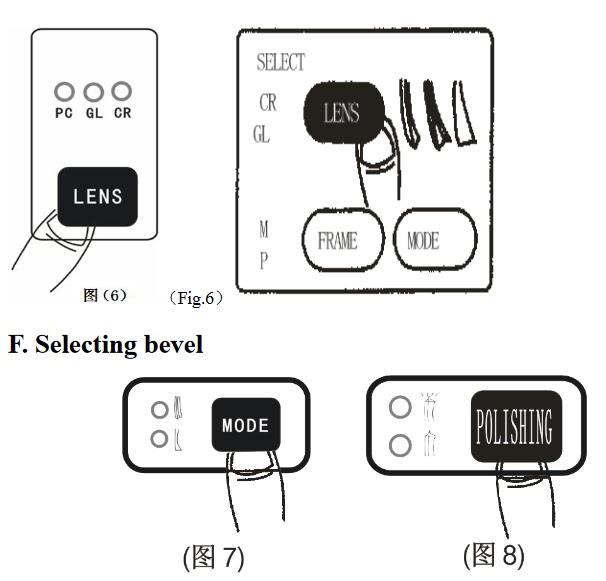

A.

Selecting lens

Selecting lens

·

Press

lens selector button to select glass lens or CR lens

Press

lens selector button to select glass lens or CR lens

NOTE: It is initially set as GL lens mode when turn on power switch

a.

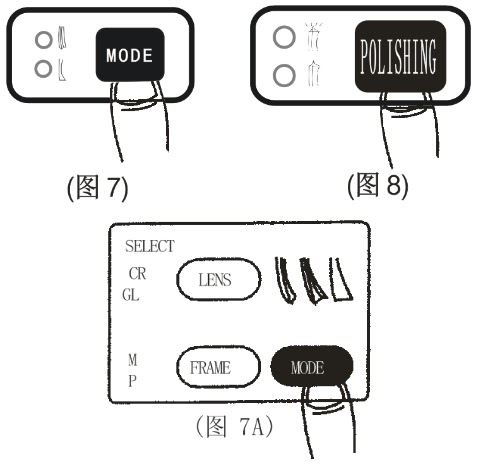

Press MODE button to alternate modes between bevel

and rimless

Press MODE button to alternate modes between bevel

and rimless

b.

When “rimless” or “bevel” is selected, you can also

select polishing or not polishing functions(Fig 7 and Fig. 8)

When “rimless” or “bevel” is selected, you can also

select polishing or not polishing functions(Fig 7 and Fig. 8)

c.

When select the “rimless”, it will process rimless

lens polishing. If you do not want polishing, press “STOP” after the second

edger of lens and then the machine will come back to the beginning

position.(Fig.7A)

When select the “rimless”, it will process rimless

lens polishing. If you do not want polishing, press “STOP” after the second

edger of lens and then the machine will come back to the beginning

position.(Fig.7A)

NOTE:

1.

When polishing with “rimless” or “bevel”,you can

choose to turn on the light upside of the button “POLISHING”, the machine will

come back to the beginning position after finishing edging.

When polishing with “rimless” or “bevel”,you can

choose to turn on the light upside of the button “POLISHING”, the machine will

come back to the beginning position after finishing edging.

2.

When the machine is not polishing while “rimless”

or “bevel”, you can chose to turn on the light under the button “POLISHING”.

The machine will come back to the beginning position after finishing edging.

When the machine is not polishing while “rimless”

or “bevel”, you can chose to turn on the light under the button “POLISHING”.

The machine will come back to the beginning position after finishing edging.

A. Start

·

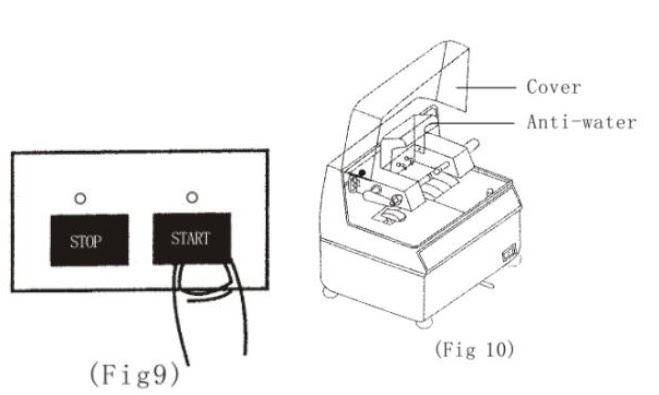

Press START button and process will start

Press START button and process will start

·

Make sure waterproof is closed when edging lens

Make sure waterproof is closed when edging lens

·

Close sound proof cover.

Close sound proof cover.

H: Shifting lens position

·

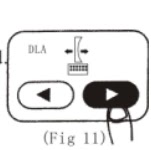

Press

< and > button to move lens above gear wheel as desired.

Press

< and > button to move lens above gear wheel as desired.

I: Changing lens size

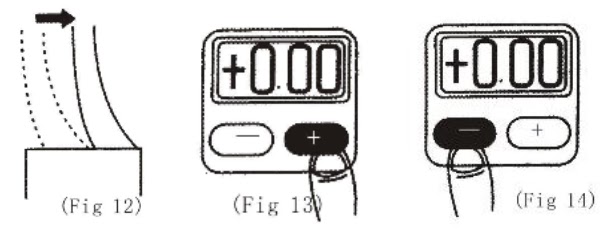

· Use + button

to make the lens size larger if its size is smaller after its testing edging.

to make the lens size larger if its size is smaller after its testing edging.

· Use _ button to make the lens size smaller if its

size is bigger after its testing edging.

size is bigger after its testing edging.

J: Re-edging

In case that the lens size is still larger after edging:

1.

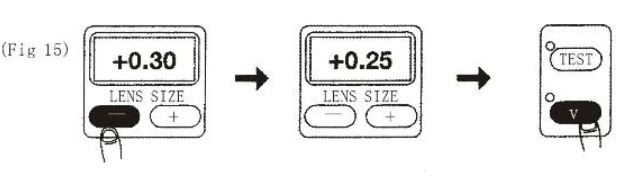

(See Fig.

15): Press button to reset lens size

(See Fig.

15): Press button to reset lens size

2.

(See Fig

15): Press V button, and the machine will re-edge lens or the second wheel

according to the desired reducing size.

(See Fig

15): Press V button, and the machine will re-edge lens or the second wheel

according to the desired reducing size.

Advantages of automatic edging machine

1.

It is

very easy to operate

It is

very easy to operate

2.

It has

high accuracy and saves cost of labour

It has

high accuracy and saves cost of labour

3.

It saves

time can edge fast

It saves

time can edge fast

4.

It can

edge thick lenses with speed.

It can

edge thick lenses with speed.

5.

It can be

operated by someone who has less experience in working with optical equipment

It can be

operated by someone who has less experience in working with optical equipment

6.

It

provides multiple finishing operations on lenses.

It

provides multiple finishing operations on lenses.

Disadvantages

1.

It has a

high cost of purchase

It has a

high cost of purchase

2.

The

tracer machine can sometimes give an inaccurate size of the frame rim

The

tracer machine can sometimes give an inaccurate size of the frame rim

Precautions/maintenance

·

Put on

your lab coat before edging

Put on

your lab coat before edging

·

Avoid dry

edging

Avoid dry

edging

·

Remove

pump from the water after use

Remove

pump from the water after use

·

Switch

off the machine after use.

Switch

off the machine after use.

·

Clean

machine both in and outside of the body after use.

Clean

machine both in and outside of the body after use.

In today’s

modern world where accuracy, flexibility and effectiveness is an important

factor in the production of lenses, the automatic edging machine helps edging

lenses with very high accuracy.

modern world where accuracy, flexibility and effectiveness is an important

factor in the production of lenses, the automatic edging machine helps edging

lenses with very high accuracy.

References

Grey, D.S. (2008). The Inclusion of Tolerance

Sensitivities in the Merit Function for Lens Optimization, SPIE 147, 63–65.

Sensitivities in the Merit Function for Lens Optimization, SPIE 147, 63–65.

Feder, D. P. (2013). Automatic optical design, Appl. Opt. 2, 1209–1226

Fischer, R. & Paul.R. (2008). Optical system

design (2nd ed.). New York: McGraw-Hill. pp. 8, 179–198.

design (2nd ed.). New York: McGraw-Hill. pp. 8, 179–198.

Kingslake, R. (2010). Lens design fundamentals,Washington D. C.: Academic Press.

Shannon, R. (2007). The art and science of

optical design, Cambridge

University Press.

optical design, Cambridge

University Press.

Smith, W. J. (2012). Modern lens design,New York: McGraw-Hill, Inc.,