Introduction — the cost of one wrong part

If you’ve ever owned the sourcing line for a new build, you know the feeling: parts that looked “available” vanish at PO time, lead times slip with every update, and the lot that finally arrives fails QA on day one. The invoice only shows unit price; it never shows the cost of idled lines, missed ship dates, or warranty exposure.

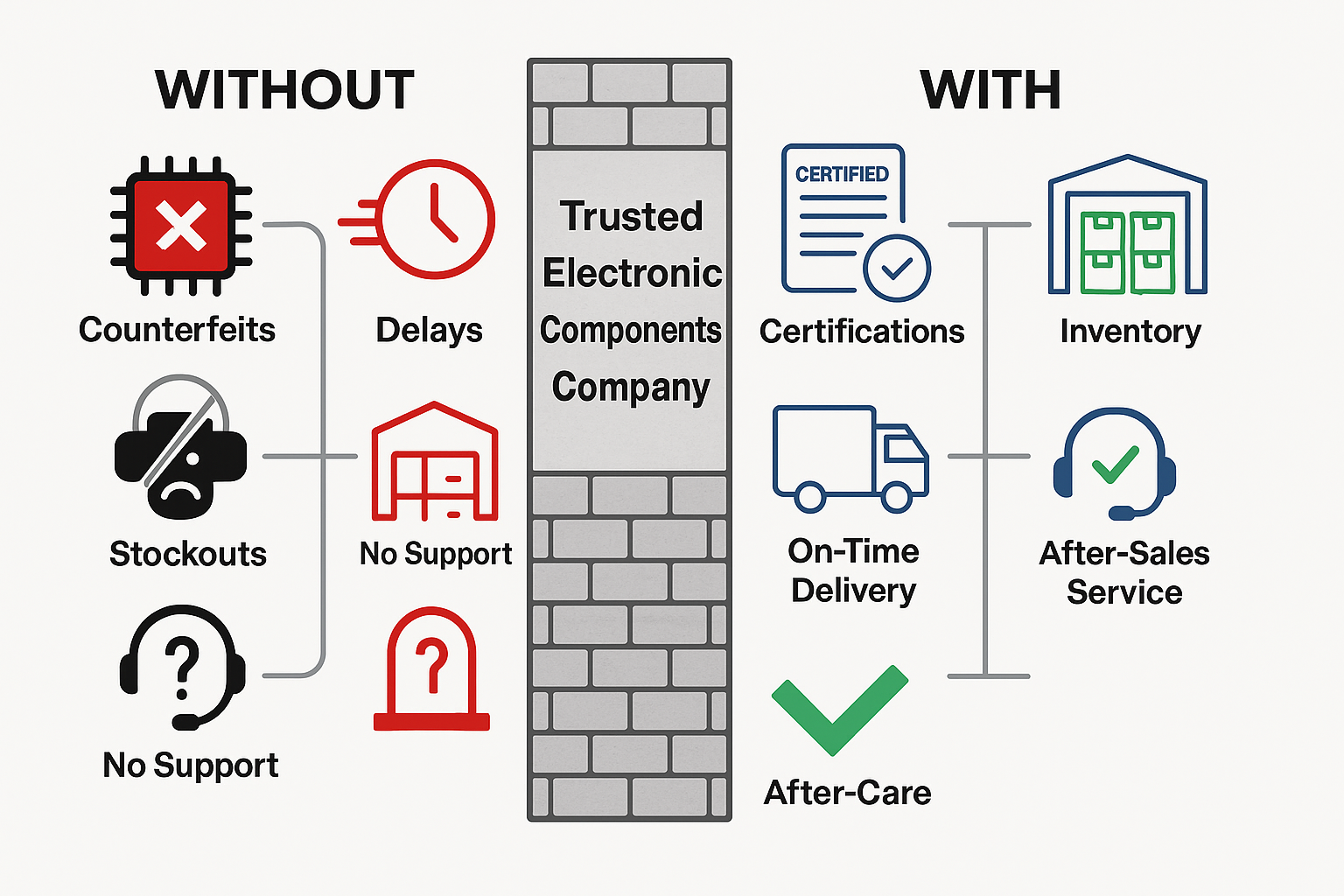

None of this is rare. Electronics move fast: short part life cycles, demand shocks, and a resale market where paperwork is optional. The real question isn’t whether risk shows up—it’s where in your workflow it lands. Price matters, sure. But in practice, control over authenticity, continuity, and accountability matters more.

This article takes the buyer’s side. We’ll map the risks you actually face, show how reliable partners reduce them, give you a field-tested checklist you can run before issuing a PO, and ground it all with component examples where the difference between a good and bad supplier becomes painfully clear.

What buyers are really up against (and what hurts most)

Let’s put names—and priorities—on the risks. They’re not equal.

Counterfeits & refurb — This is the nightmare scenario. Counterfeits can pass a visual once-over yet fail under heat, voltage, or time. Even “pulls” dressed up as new can collapse your MTBF, trigger a recall, or breach customer contracts. One bad reel in a high-volume run can turn a profitable quarter into a damage-control exercise.

Obsolescence & hard-to-find — Parts go EOL while your product still has years of field life left. In automotive, industrial, medical, and comms, redesign + recertification isn’t a sprint; it’s a budget line and a calendar you didn’t want. If you can’t secure last-time-buy stock or a vetted alternate, your roadmap becomes fiction.

Lead-time slip & allocation — A $5 regulator can stall a $5M shipment. Soft promises (“next week”) are not a plan; they’re a liability. Your factory schedule, workforce planning, and revenue recognition all depend on parts turning up when the MRP says they must.

No warranty, no recourse — Some sellers disappear after payment. No traceability, no RMA, no help when a failure analysis points to incoming quality. That’s not a supply chain—it’s gambling.

How a Global IC Supplier Actually Reduces Your Risks

A strong supplier doesn’t just quote fast; they change the math of your risk.

Authenticity you can verify

End-to-end traceability, documented chain of custody, and adherence to ISO/RoHS/ESD controls make counterfeits the rare exception instead of a recurring fear. Good partners offer evidence, not slogans: C of C, test results, and batch history on request.

Continuity from a global IC supplier

Serious distributors hold stock and operate multi-site warehouses to buffer shocks. That’s how lines keep moving when allocation hits. In real schedules, working with a global IC supplier can be the difference between “ship on Friday” and “slip the quarter.”

Lifecycle & shortage management

Proactive lifecycle monitoring, EOL alerts, and cross-reference guidance give you options before you’re cornered. When an exact match is unobtainable, a vetted alternate with equivalent specs—and a test plan—keeps your project alive.

Warranty and accountability that matter

Clear warranty terms and a documented return process mean you’re not alone if something goes wrong. That safety net is invisible when everything works; it’s priceless the day it doesn’t.

Due-Diligence Checklist with a Trusted Electronic Components Company

Start here, and you’ll avoid most landmines.

Quick rule #0: Choose a trusted electronic components company

Treat claims as hypotheses—ask for proof. A reliable partner won’t hesitate to provide documentation, from ISO certificates to batch test reports.

1) Verify certifications

Ask for ISO certificate numbers and the issuing registrar. Spot-check them on the registrar’s site. Real certificates are traceable; doctored PDFs aren’t.

2) Demand traceability

Request manufacturer part numbers, date/lot codes, and C of C. For sensitive builds, ask how the supplier prevents commingling across lots and what tests are performed on incoming goods.

3) Test before you trust

For first-time buys or high-risk parts, place a pilot order for electrical/thermal testing. If you can’t test internally, ask the supplier which accredited labs they use and what reports they provide.

4) Interrogate lead times

“How many on hand? Where? When can you ship from that site?” Real inventory comes with location, bin counts, and ship windows. “We can source next week” is a red flag—press for specifics or walk.

5) Read the quality policy

Look for written RMA terms, DOA handling, moisture-sensitivity procedures (MSL), and storage/packaging standards (e.g., JEDEC). If the policy fits in two vague sentences, it doesn’t exist.

6) Ask for references

One or two logos or a short note from a repeat buyer in your segment says more than a glossy homepage.

7) Clarify risk-sharing

If a lot fails, who pays for return freight? How quickly can replacements ship? You’ll never care—until you really, really care.

Run that list and you’ll learn, fast, who is worth your PO.

Mini-cases: where the supplier made (or saved) the quarter

Abstract advice is easy; production is not. These compact, real-world patterns show how a reliable supplier plays out on the floor.

Case A — MAX3673ETN+ frequency synthesizer (comms)

A telecom team hit bring-up with a tight RF budget and a part on allocation. A “too good to be true” lot got them through power-on, then failed thermal margin testing. A vetted distributor replaced the batch with original, same-date-code parts, and the design hit spec without retuning the entire chain. Days lost? Some. Months saved? Many.

Case B — NJW1504V-TE1 PLL (precision control)

An industrial OEM faced an EOL notice mid-lifecycle. The initial plan—redesign the clocking tree—would have pushed certification by a season. Their supplier located clean stock for short-term continuity and proposed an alternate PLL with a pin-compatible footprint and verified jitter performance. The line stayed live while the controlled migration happened off the critical path.

Case C — DS1086HU-CO2+T programmable clock (low-volume custom)

A niche device needed a tweakable timing solution. Market listings existed, but traceability didn’t. The preferred partner shipped pre-baked inventory with documentation, plus a small set pulled for application testing. Engineering signed off in a week instead of a quarter spent chasing mystery stock.

Case D — NJM567D PLL (industrial sensing)

A plant went down for nearly two weeks after a surprise shortage. The supplier that had promised “next week” kept moving the goalposts. A reliable distributor delivered from a secondary warehouse, then locked a rolling buffer with minimums to prevent a repeat. OEE recovered; finance stopped burning weekends.

Case E — Micron memory ICs (everything uses memory)

A team opted for cheaper gray-market memory and paid for it in field failures. The replacement program was painful and public. A certified supplier switched them to original Micron with warranty and traceable lots, closing the loop on both quality and optics.

The thread through all five? Documentation, predictability, and help when it’s messy. That’s what you actually buy.

Practical takeaways you can use this week

- Sort risks by severity, not convenience. Counterfeit and obsolescence belong at the top; schedule and cost follow.

- Buy proof, not promises. Certificates, lot codes, and test reports should be normal business, not a favor.

- Pilot orders save programs. Small, fast validation buys cost less than one week of a stalled line.

- Design with alternates in mind. Keep second sources on your AVL where possible; work with partners who will propose vetted equivalents when exacts are scarce.

- Write recourse into the PO. Warranty, RMA windows, and turnaround times are not afterthoughts.

If those habits feel “extra,” ask anyone who’s lived through a mid-build shortage or a counterfeit incident. Process beats heroics every time.

Conclusion — choose your risk, or it chooses you

In component procurement, risk isn’t a plot twist; it’s the setting. You can chase the lowest quote and hope, or you can structure the work so quality and continuity are boringly predictable. The second path isn’t luck. It’s partner choice, documentation discipline, and a willingness to say “show me” when a promise sounds easy.

You don’t need a binder of theory to get there. You need a handful of checks you run every time, and partners who are happy to pass them. When you work with a global IC supplier that holds inventory, proves authenticity, and stands behind the shipment, schedule risk goes down. When your short list is built around a trusted electronic components company that welcomes scrutiny, quality risk goes down. And when both go down together, the rest of your P&L tends to behave.

The invoice will still show unit price. Your deliverables will show the rest.