Minimum

Re-order Level:

This is the balance of stock at which a new order for stock is placed. This

re-order level is expressed mathematically as;

Re-order Level:

This is the balance of stock at which a new order for stock is placed. This

re-order level is expressed mathematically as;

Maximum usage (consume) x Maximum

lead time

lead time

Re-order

Quantity:

This is the quantity that is been ordered or placed on order. It is expressed

mathematically as;

Quantity:

This is the quantity that is been ordered or placed on order. It is expressed

mathematically as;

Maximum stock level – Re-order level

+ (Minimum usage x Minimum lead time)

+ (Minimum usage x Minimum lead time)

Maximum

Stock Level: This

is the highest stock level authorised and maintain by management. It is

expressed as;

Stock Level: This

is the highest stock level authorised and maintain by management. It is

expressed as;

Re-order level + EOQ – (Minimum

usage x minimum lead time)

usage x minimum lead time)

Average

Cost: This

is the stock level which is determined by;

Cost: This

is the stock level which is determined by;

Maximum stock level + minimum stock

level ÷ 2

level ÷ 2

Stock

Turnover Ratio: This

ratio inform management about the rate at which stock is used. It is expressed

mathematically as;

Turnover Ratio: This

ratio inform management about the rate at which stock is used. It is expressed

mathematically as;

Lead

Time:

This refers to the time interval between ordering for stock and actual receipts

of stock.

Time:

This refers to the time interval between ordering for stock and actual receipts

of stock.

Minimum

Stock Level: This

is the point at which the stock level is at the minimum. It is represented as

Stock Level: This

is the point at which the stock level is at the minimum. It is represented as

Re-order level – (Average usage x

average lead time)

average lead time)

Example

Asaba Manufacturing Company Plc

produces a product X, the following information relate to material which the

company uses in its production activities;

produces a product X, the following information relate to material which the

company uses in its production activities;

Lead time, maximum = 10 months

Lead time, minimum = 5 months

Material use annually = 1,800kg

Ordering cost N5 per order

Storage cost N2 per item

Price per unit/per kg or material N3

Usage of material: Maximum usage,

800kg per month

800kg per month

Minimum

usage, 300kg per month

usage, 300kg per month

Average

usage 550 per month

usage 550 per month

Total acquisition cost of material

consume annually isN54,000

consume annually is

Required

1.) EOQ

2.) Re-order

level

level

3.) Maximum

stock level

stock level

4.) Minimum

stock level

stock level

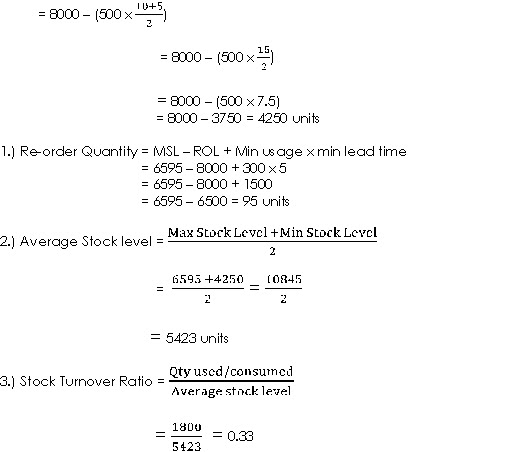

5.) Re-order

quantity

quantity

6.) Average

stock level

stock level

7.) Stock

turnover level

turnover level

Solution

1.) EOQ

(Economic Order Quantity)

(Economic Order Quantity)

Where;

O = Ordering cost

D = Annual demand

C = Carrying cost

2 = Constant

2.) Re-order level =

Maximum usage x Minimum lead time

Maximum usage x Minimum lead time

= 800 x 10 = 8000 units

3.) Maximum Stock level =

ROL + EOQ – Min Usage x min lead time

ROL + EOQ – Min Usage x min lead time

= 8000 + 95 – (300 x 5)

= 8000 + 95 – 1500

= 8095 – 1500 = 6595

units

units

4.) Minimum

Stock Level = ROL – (Avg usage x Avg lead time)

Stock Level = ROL – (Avg usage x Avg lead time)